News

-

Straight seam steel pipe acceptance method and problem-solving

Acceptance of straight seam steel pipe: 1. The inspection and acceptance of straight seam steel pipes shall be carried out by the technical supervision department of the supplier. 2. The supplier guarantees that the delivery of straight seam steel pipes complies with the provisions of the corresp...Read more -

What is the difference between straight seam steel pipe and seamless steel pipe

A. Different categories 1. Straight seam steel pipe: divided into metric electric welded steel pipe, electric welded thin-walled pipe, transformer cooling oil pipe 2. Seamless steel pipes: seamless pipes are divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, jacki...Read more -

Causes of problems caused by improper heat treatment of seamless steel pipes

Improper heat treatment of seamless steel pipes is likely to cause a series of production problems, resulting in greatly reduced product quality and turning into waste products. Avoiding mistakes that are easy to make during heat treatment is saving money. What problems should we pay attention to...Read more -

How to carry out anti-corrosion treatment of spiral steel pipe for water delivery

If the spiral steel pipe for water transportation is used to transport tap water or drinking water, the inner wall is usually made of IPN8710 non-toxic anti-corrosion coating, and the outer wall is made of epoxy coal tar pitch for anti-corrosion. Of course, it can also be used for inner and outer...Read more -

Large diameter welded steel pipes production process

What is the production process of large diameter welded steel pipe? Next let’s take a look 1: Conduct physical and chemical inspection of raw materials such as strip steel coils, welding wires, and fluxes. 2: The head-to-tail butt joint of the strip steel adopts single-wire or double-wire s...Read more -

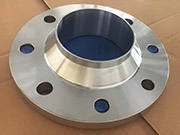

Introduction to the quality process and characteristic uses of large-diameter steel flanges

Large-diameter steel flange is a kind of steel flange, which is widely used and promoted in the machinery industry, and has been well received and favored by users. Large-diameter steel flanges are widely used, and the scope of use is determined according to different characteristics. They are mo...Read more