News

-

Heat treatment of steel pipe fittings

1. The steel pipe fittings formed by cold working are subjected to heat treatment for stress relief after forming. 2. For steel pipe fittings formed by thermal processing, heat treatment should be carried out for chrome-molybdenum steel and stainless steel materials; for carbon steel materials, h...Read more -

The service life of galvanized steel pipe fittings

The service life of galvanized steel pipe fittings is long, but the service life is different in different environments: 13 years in heavy industrial areas, 50 years in oceans, 104 years in suburbs, and 30 years in cities. The yellow water is directly caused by galvanizing. Due to the threaded co...Read more -

What are the advantages of 304 stainless steel pipe fittings

①Advantages in material performance: 304 stainless steel pipe fittings are made of stainless steel as the name suggests. The strength of stainless steel is 3 times that of copper pipes, and 8 to 10 times that of PPR pipes. It can withstand the impact of high-speed water flow at 30 meters per seco...Read more -

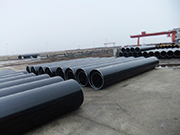

Pretreatment and application of straight seam steel pipe

Pre-treatment of straight seam steel pipes: non-destructive testing inside the welds Since the pipes are extra-large steel pipes in water supply projects, especially steel pipes with a thickness of t=30mm are used as pipe bridges, which not only bear internal water pressure but also bear the bend...Read more -

The series of diameter dimensions and heating physical deformation stipulated in the standard of straight seam steel pipe

Series of diameters specified in the standard for straight seam steel pipes: the nominal diameter of straight seam steel pipes refers to the series of diameters specified in the standards for straight seam steel pipes. For straight seam steel pipes, pipe fittings, valves, etc., the nominal straig...Read more -

The difference between fixed welding joints, rotating welding joints, and prefabricated welding joints in steel pipeline welding

Fixed welding means that the joints of the steel pipes cannot be moved after being assembled, and the welding is performed according to the change of the welding position (horizontal, vertical, upward, and mid-level changes) during the welding process. Rotating the welding port is to rotate the w...Read more