News

-

Rust removal method and production process of large-diameter straight seam steel pipe

Large-diameter straight seam welded pipe is a general term. It is produced by steel strips. All pipes welded by high-frequency welding equipment are called straight seam welded pipes. (It is named because the welding part of the steel pipe is in a straight line). According to different uses, ther...Read more -

What details should thick-walled steel pipes go through before use

The selection of welding methods for thick-walled steel pipes should be based on the material and wall thickness of thick-walled steel pipes. Because different welding methods have different arc heat and arc force, different welding methods have different characteristics. For example, the charact...Read more -

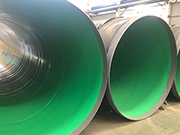

Construction, installation, and inspection methods of plastic-coated steel pipes

First, construction and installation of plastic-coated steel pipes 1) It should be carried out by the “Technical Code for Plastic-coated Composite Pipe Pipe Engineering for Building Water Supply” CECS125:2001. 2) The following construction machines and tools should be used for plastic...Read more -

Differences between hot-rolled seamless steel pipes and cold-rolled seamless steel pipes

From the processing technology: hot rolling is hot processing, and cold drawing is cold processing. Hot rolling is rolling above the recrystallization temperature, and cold rolling is rolling below the recrystallization temperature; From the appearance: the surface of cold-rolled seamless steel p...Read more -

Geometric characteristics of large-diameter steel pipe sections

(1) Its node connection is suitable for direct welding, without node plates or other connectors, which saves both labor and materials. (2) When necessary, concrete can be poured inside the pipe to form a composite component. (3) The geometric characteristics of the pipe section are good. The pipe...Read more -

Process flow of steel elbows commonly used in industrial projects

Seamless steel elbow: Steel elbow is a kind of pipe fitting used at the end of the pipeline. It accounts for about 80% of all the pipe fittings used in the pipeline system. Usually, different forming processes are selected for steel elbows of different materials or wall thicknesses. Common seamle...Read more