what is galvanized steel pipe?

Galvanized steel pipe is a type of steel pipe that has been coated with a protective layer of zinc to prevent corrosion. The process of galvanization involves immersing the steel pipe in a bath of molten zinc or using an electroplating method to apply a thin layer of zinc to the surface. This zinc coating serves as a barrier between the steel and the surrounding environment, protecting the pipe from rust and corrosion.

Types: Galvanized welded steel pipe, galvanized seamless steel pipe

Materials: Carbon steel

Connection type: threaded

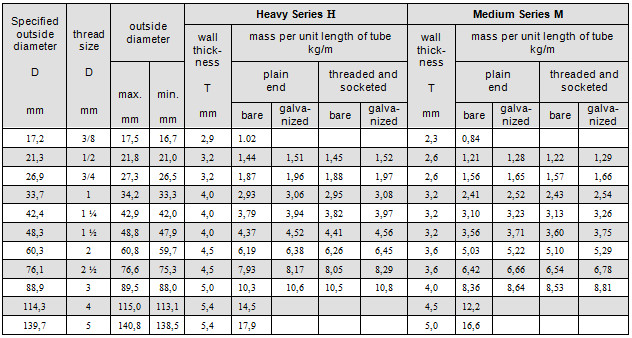

Size range:1/8″-36″

Schedule: sch40, sch80, sch120, sch160, XH, XXH

Length of the galvanized tubes

– in diameter 4 – 16 mm 6000 + 100 mm

– in diameter 18 – 42 mm 6000 + 50 mm

Tolerances of the zinc coated tubes

– tolerances of the outside diameter:

– diameter between 4 – 30 mm ±0,08 mm

– diameter between 35 – 38 mm ±0,15 mm

– diameter up to 42 mm ±0,20 mm

– tolerances of the inside diameter are according to EN 10305-4

– tolerance of the wall thickness ± 10%

A53 Pipe Materials & Manufacture

Steel materials used to create seamless pipe and welded pipe must be produced via open hearth, electric furnace, basic oxygen, or any combination of these processes. All weld seams in electric-resistance welded A53 Grade B pipe must be heat treated after welding to a minimum of 1,000°F (540°C) to eliminate untempered martensite.

Galvanized A53 Pipe

If ordered galvanized, A53 seamless pipe must be coated inside and out via the hot-dip process. Zinc used for galvanized coatings must conform to Specification B6. The weight of this coating must not be less than 1.8 oz./ft2 (0.55 kg/m2). Test specimens for coating weight testing will be cut in approximately 4” lengths.

Permissible Variation in Wall Thickness

The minimum wall thickness at any point in a length of A53 steel pipe must not be more than 12.5% less than the specified wall thickness.

Permissible Variations in Outside Diameter

For ASTM A53 steel pipe NPS 1-1/2 and smaller, outside diameter must not exceed 1/64” over and 1/32” under specified diameter. For A53 pipe NPS2 and larger, outside diameter must not exceed 1% over and 1% under specified diameter.

Hydrostatic Testing of ASTM A53 Pipe

Separate hydrostatic inspection test pressures are specified for plain end, threaded, and coupled A53 steel pipe. Minimum hydrostatic test pressure for NPS 3 and under is 2,500 psi; minimum test pressure for sizes over NPS 3 is 2,800 psi. Pressure must be maintained for a minimum of 5 seconds, for all sizes.

Mechanical Testing of ASTM A53 Pipe

Electric-resistance welded ASTM A53 steel pipe of NPS 8 and larger must be transverse tested. Sending test (cold) is required for STD and XS-NPS 2 and under, and for XXS-NPS 1-1/4 and under. Flatten testing is required for NPS 2 and larger STD and XS A 53 pipe; flatten testing is not required for XXS pipe.

| Size | OD | 1/8” -24” (5.15mm-714mm) |

| Wall Thickness | 0.4mm-26mmSCH20,SCH40,STD,XS,SCH80,SCH160,XXS | |

| Length | Less than 12m | |

| Steel material | Q195 → SS330,ST37,ST42Q235 → SS400,S235JR

Q345 → S355JR,SS500,ST52 |

|

| Standard | ASTM A53, BS1387-1985 | |

| Zinc Weight | 120g,270g,400g,500g,550g20μm ,40μm ,60μm,70μm,80μm | |

| Usage | 1)low pressure liquid, water, gas, oil, line pipe2)construction

3)fence, door pipe |

|

| Ends | 1) Plain2) Beveled

3) Thread with Coupling or cap 4) Chamfer 5) Groove 6) Screw |

|

| End protector | 1) Plastic pipe cap2) Iron protector | |

| Surface Treatment | 1) Bared2) Black Painted (varnish coating)

3) Galvanized 4) Oiled 5) PE,3PE, FBE, corrosion resistant coating, Anti corrosion coating. |

|

| Technique | Electronic Resistance Welded (ERW )Electronic Fusion Welded (EFW)

Double Submerged Arc Welded (DSAW) |

|

| Welded Line Type | Longitudinal | |

| Section Shape | Round | |

| Inspection | With Hydraulic Testing, Eddy Current , Infrared Test | |

| Package | 1) Bundle,2) Bags | |

| Delivery | 1) Container2) Bulk carrier | |

| Port of Shipment | Xin gang Port, Tianjin, China | |

| Date of Delivery | According To The Quantity And Specification Of Each Order | |

| Payment | L/C T/T | |

| Others | Fitting as screws and flange also can be supplied. | |

Chemical Requirements of ASTM A53

| Carbon | Manganese | Phosphorus | Sulfur | Copper | Nickel | Chromium | Molybdenum | Vanadium | |

| Composition, max. % | |||||||||

| Type S (seamless pipe) & Type E (electric-resistance-welded) | |||||||||

| Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Grade B | 0.3 | 1.2 | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| Type F (furnace-welded pipe) | |||||||||

| Grade A | 0.3 | 1.2 | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

Application of galvanized steel pipe:

1)Water distribution: Galvanized pipes were historically a popular choice for water supply systems.

2)Plumbing: Galvanized steel pipes were commonly used in plumbing systems in older buildings.

3)Gas lines: Galvanized steel pipes are sometimes used for natural gas distribution.

4)Conduit for electrical wiring: Galvanized steel pipes can serve as conduits for electrical wiring and are used in some electrical installations.

BESTAR is a China-leading product service provider and exporter of steel pipe. We have engaged in the steel pipe industry for 30years with rich exprience and strong strengths. We supply high quality galvanized steel pipes, please feel free to contact us for a quote.

Post time: Oct-31-2023