Duplex Steel Welded Pipe

Duplex Steel Welded Pipe Details

What is a Duplex Steel Welded Pipe?

Duplex steel welded pipes are made of two different types of stainless steel, which are also known as austenitic and ferritic steel. Duplex steel is a combination of both types of steel which gives it a higher strength, corrosion resistance, and better weldability than either of the two types of steel alone. Duplex steel welded pipes are used in many industries including the chemical, petrochemical, marine, and food processing industries. They are used in a variety of applications including pipelines, pressure vessels, boilers, tanks, and condensers. Duplex steel welded pipes are also used in the construction industry for a variety of purposes such as structural frames, piping systems, and for other general fabrication purposes.

Duplex Steel Welded Pipe & Tube Standards, Specification & Grades

| Standard | ASTM A790, A789, A815 / ASME SA790, SA789, SA815 |

| Grades | UNS S31803, UNS S32205 |

| Dimensions | ASTM, ASME and API |

| Size | 1/2″NB TO 12 “NB IN |

| Thickness | 0.5-45mm |

| Outer Diameter | 6.0-630mm |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80 |

| Type | Welded |

| Length | Single Random, Double Random & Cut Length |

| Form | Round, Square, Rectangular, hydraulic etc. |

| End | Plain End, Beveled End, Treaded |

Duplex Steel Welded Pipe Dimension Chart

| Pipe Types | Out diameter | Wall thickness | Length |

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Welded Pipe (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

Duplex Steel Welded Tube Dimension Chart

| Tube Types | Out diameter | Sizes | Length |

| NB Sizes (in stock) | .0035” ~ 8” | 1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 1″, 1.25″, 1.5″, 2″, 2.5″, 3″, 4″, 5″, 6″ | Cut to length |

| Welded Tube (ERW Tube) (in Stock + Custom Sizes) | 6.35 mm OD To 152 mm OD | As per requirement | Cut to length |

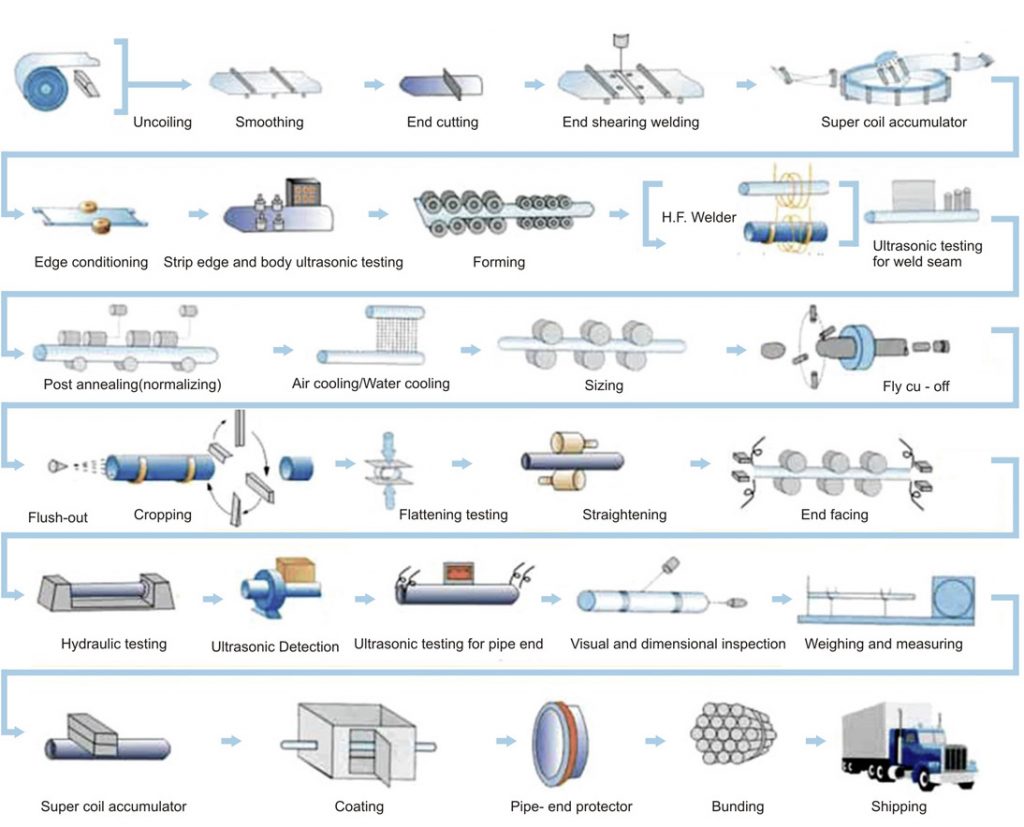

Manufacturing Process of Duplex Steel Welded Pipe

Application of Duplex Steel Welded Pipe

1. Chemical processing, transport and storage

2. Oil and gas exploration and offshore rigs

3. Oil and gas refining

4. Marine environments

5. Pollution control equipment

6. Pulp & paper manufacturing

7. Chemical process plant